✅ Various cutlery shapes available

✅ Special-purpose designs

✅ Ergonomic optimization

💡 Your idea, our craftsmanship!

🔥 Laser engraving

🔥 Hot stamping

🔥 Embossing

🌿 Let your customers remember your brand with every use!

📦Kraft bags & biodegradable pouches

📦 Custom boxes & paper packaging

📦 Individual OPP packaging

🚀 Turn your packaging into a powerful branding tool!

Own factory + long-term partners, flexible capacity adjustment, ensuring steady deliveries.

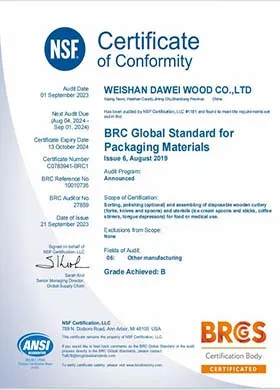

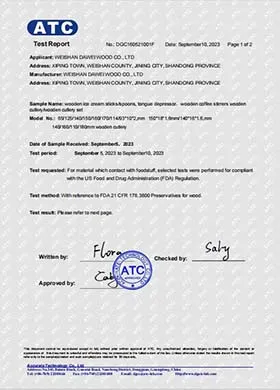

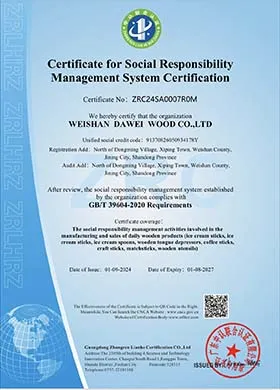

FSC-certified materials, full-process inspection, meeting FDA, LFGB, and global standards.

OEM/ODM available, custom sizes, logos, and packaging to enhance your brand.

Deep knowledge of international regulations, multi-channel marketing (website, B2B, trade shows) to connect you with the right market.

Sea, air, and rail shipping options, flexible trade terms (FOB, CIF, DDP), ensuring on-time delivery.

Trackable orders, priority production, and dedicated support for a seamless cooperation.

Using internationally leading CNC woodworking machines, it achieves ±0.1mm precision to ensure perfect custom size requirements.

Equipped with high-speed automatic feeders and visual recognition sorting systems, it processes over 10K pieces per hour, boosting efficiency.

Using the LaserPro X200, we engrave logos and print patterns, completing 100K+ tasks daily for brand personalization.

With automatic sealing and packing machines, we package 50+ boxes per minute, ensuring product safety and efficient logistics.

We purchase over 1,000 tons of FSC-certified wood annually. Every batch comes with verified FSC certificates and full traceability reports. Before storage, wood undergoes rigorous testing—including density, moisture content (8%-12%), and non-toxic treatment—to ensure defect-free material that meets international environmental standards.

All products are tested in internationally recognized laboratories to comply with food safety standards such as FDA and LFGB. For food contact items (e.g., knives, forks, spoons, coffee stirrers), every batch undergoes migration testing to prevent harmful substance release. Over 300 batch tests are conducted each year, underscoring our unwavering commitment to safety and quality.

We collaborate with leading international certification bodies like SGS and TÜV to audit our production facilities and processes annually. Our independent quality team uses precision calipers, projectors, hardness testers, and tensile testing machines for comprehensive sampling inspections—verifying dimensions, appearance, and durability to ensure consistently high-quality products.

+86 19121501176

At WonBon, our sales team is more than just a bridge between you and the factory—they’re your reliable partner throughout the entire sourcing journey. With years of experience in international trade and in-depth product knowledge, our multilingual sales specialists provide:

Your Global Partner from Inquiry to Delivery

We understand not just what you ask for—but why you need it. That’s how we help you move faster, reduce risk, and win your market.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Far far away, behind the word mountains, far from the countries Vokalia and Consonantia, there live the blind texts. Separated they live in Bookmarksgrove right at the coast

Using internationally leading five-axis CNC woodworking machines, it achieves ±0.01mm precision for perfect dimensions.

Equipped with high-speed automatic feeders and visual recognition sorting systems, it processes over 10K pieces per hour, boosting efficiency.

Using the LaserPro X200, we engrave logos and print patterns, completing 100K+ tasks daily for brand personalization.

With automatic sealing and packing machines, we package 50+ boxes per minute, ensuring product safety and efficient logistics.

WonBon®: Your Trusted Partner in Custom Eco-Wood Solutions — 15 +Years of Integrated Manufacturing & Global Supply Chain Leadership.